TRU Compliance Equipment Testing Project

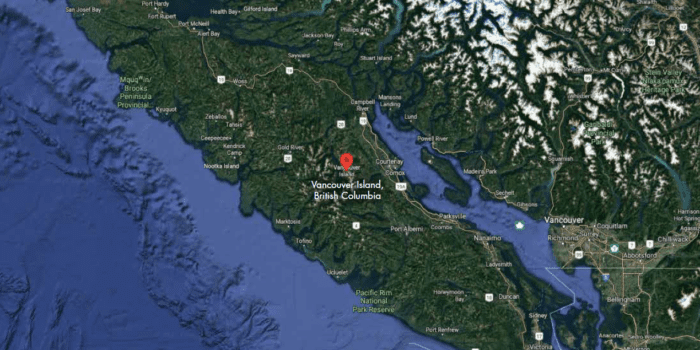

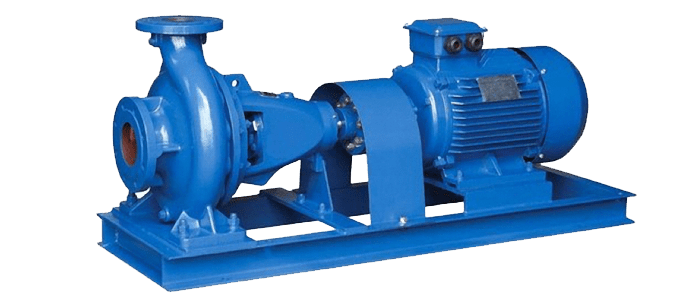

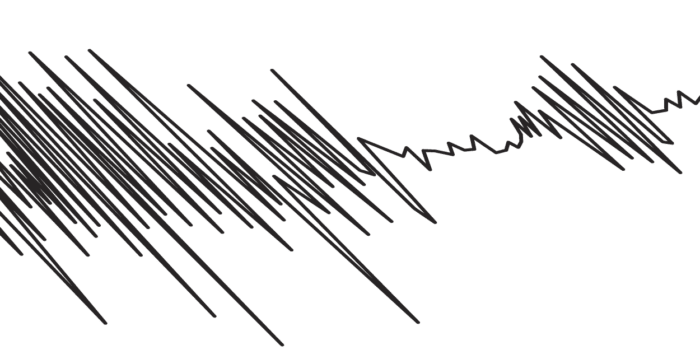

TRU Compliance, the product certification body of Structural Integrity Associates, has been awarded a contract to assist BC Hydro in qualifying and better understanding the seismic vulnerability of critical equipment used to control its spillway gates. As part of the…