THE IMPORTANCE OF PRODUCT ANALYSIS

Analysis can always be used as a part of a well-structured seismic certification program as a means to reduce potential testing requirements or cover unique mounting configurations.

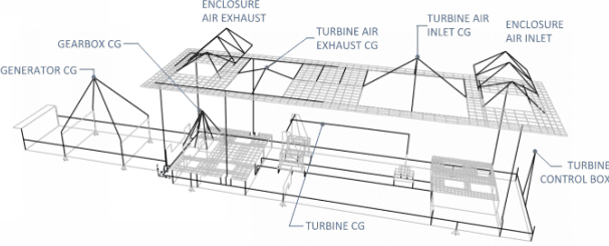

For systems without active parts (e.g. tanks), analysis is used as the sole basis of certification. On large systems comprising active subcomponents, analysis can be used to develop seismic demands on subcomponents for shake table testing.

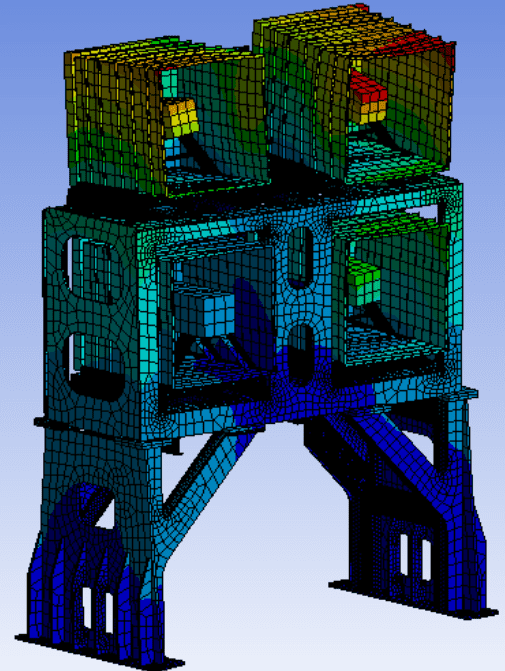

TRU Compliance regularly performs seismic analysis and design in accordance with code provisions for seismic certification and unique mounting arrangements. Additionally, analysis and structural design is used prior to testing to increase the likelihood of successful testing and certification.

CERTIFICATION BY ANALYSIS

TRU Compliance issues certifications based on analysis alone. These certifications meet requirements for position retention and containment of hazardous materials. While they do not specifically demonstrate the product will remain functional – testing is required to prove functionality of active components – the structural analysis will calculate the seismic level that the equipment can “withstand” without loss of stability.

PRETEST ANALYSIS

As a service to manufacturers planning a seismic test, TRU offers a basic pre-test fitness analysis which calculates the seismic level that is likely to be achieved. It also shows where the weak points are so the manufacturer can design upgrades to increase the change the equipment passes the seismic test.

MULTI-COMPONENT SYSTEMS

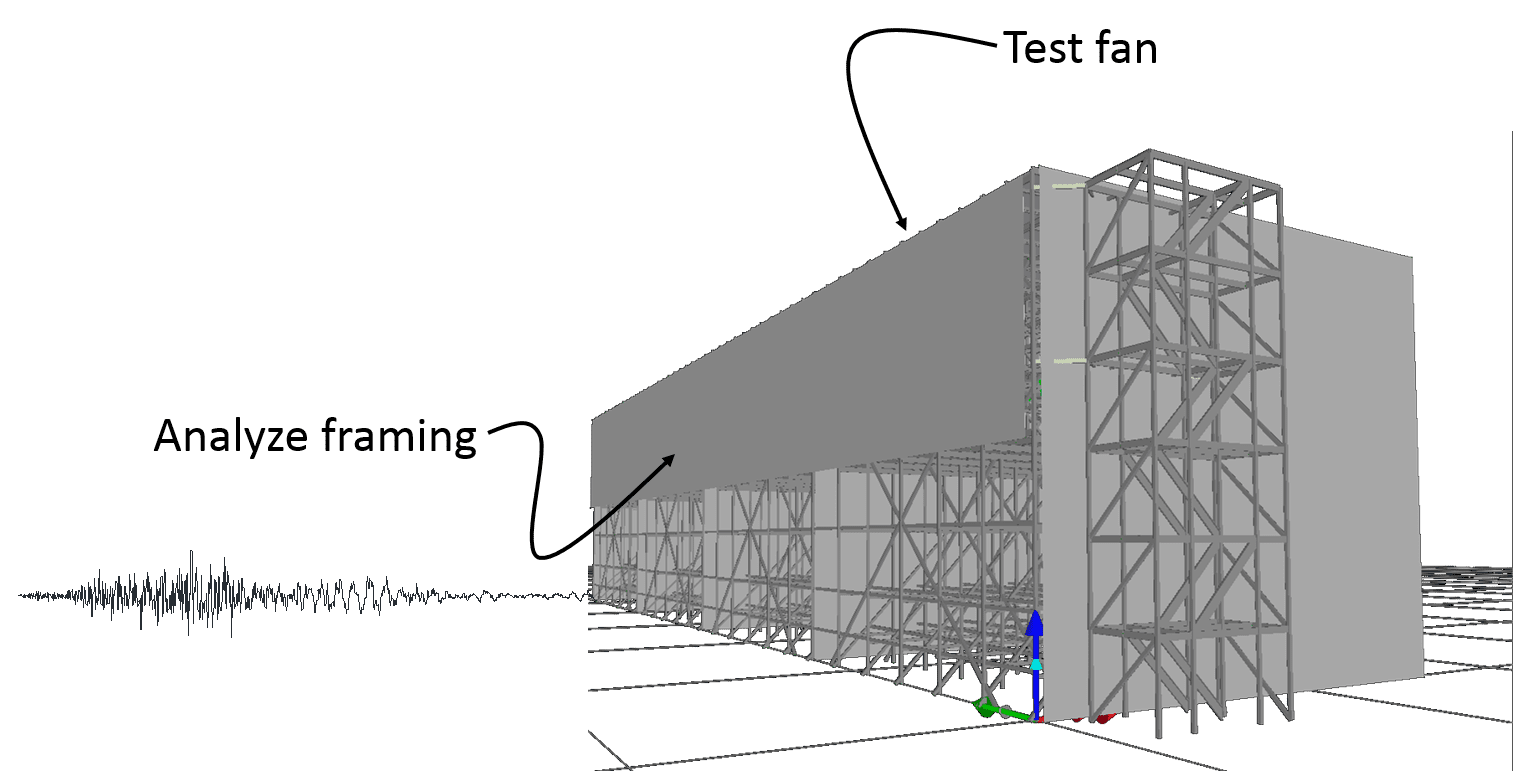

Some equipment is too large to feasibly test on a shake table, or has some active components surrounded by large areas of framing or structural housing. In these circumstances, it is often most cost-effective to test the smaller active components to an in-structure seismic level and analyze the framing and connections to active components to achieve seismic compliance.